A goodwill gesture constructed with a 3D printer and a little extra time

Published: July 30, 2020 / Author: Carol Elliott

Here’s a point we can probably all agree on when it comes to wearing masks: They are not exactly comfortable.

Specifically, they chafe your ears.

Kevin Zufelt (EMBA’21)

In the maelstrom of daily headlines around the COVID-19 pandemic, that small observance might not amount to breaking news. But for Kevin Zufelt, it suggested an opportunity to help.

When the pandemic shut down much of normal life in the spring, Zufelt (EMBA ’21) was in the midst of transitioning to a new job as a data engineer with W.L. Gore & Associates (makers of Gore-Tex) and was about midway through the Notre Dame Executive MBA program. Holed up in his Pottstown, Pennsylvania, home, he worked remotely and attended classes online, and did a lot of home improvement projects.

Several years before, Zufelt had purchased a 3D printer, thinking he’d make a few toys for his nieces and nephews. “Then I saw a news article about a Boy Scout who used a 3D printer to print off something called ear savers,” said Zufelt. “I printed off a couple for myself to see how they worked, and they did give my mask a much tighter fit.”

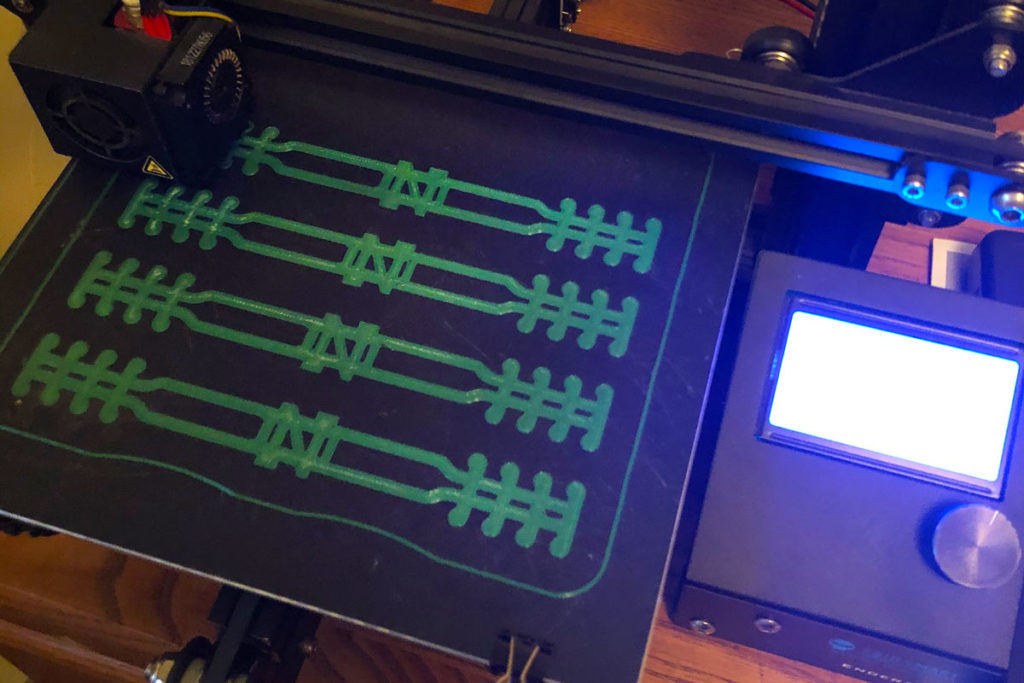

The ear saver is a plastic strip with several brackets on each end made to hold the elastic straps of a face mask to relieve the pressure on the ears — a common complaint especially from health care workers who have to wear masks for lengthy periods of time.

Zufelt knew several his EMBA classmates worked in the medical field and were now on the front lines of the pandemic. He began to reach out to them and offered to provide the ear savers free of charge. He found a pattern online, made a few alterations, created a few trial versions until he was satisfied with the design, then set his printer to print.

“It takes about 90 minutes to print five ear savers, but once I set the printer to run, I can walk away,” he said. “There’s a lot of downtime in-between.”

“It takes about 90 minutes to print five ear savers, but once I set the printer to run, I can walk away,” he said. “There’s a lot of downtime in-between.”

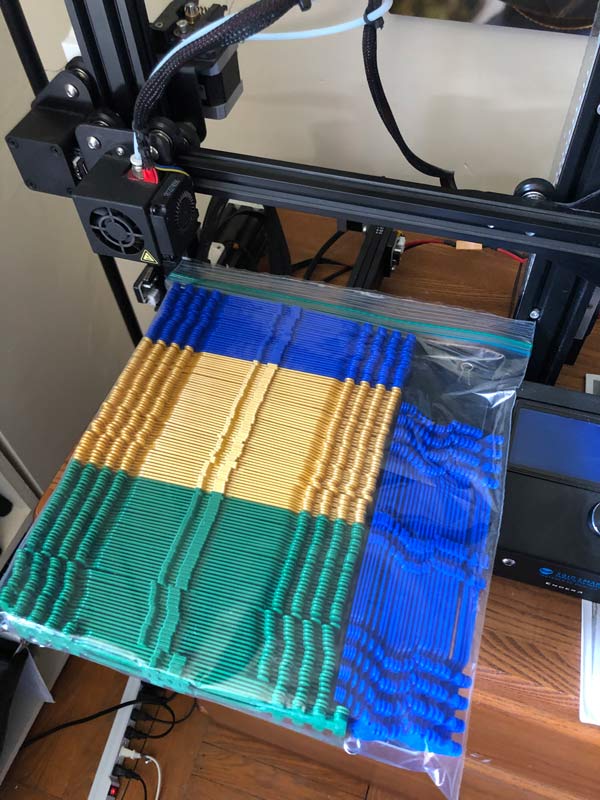

Zufelt has printed several hundred for Beacon Medical System in South Bend, Indiana, where one of his EMBA classmates is a doctor and several others work in various roles. He created a custom version in Notre Dame colors of blue, gold and green for the Mendoza College of Business staff. And he made 300 ear savers for the Mercy Home for Boys & Girls in Chicago, a Catholic organization serving children and families in need.

In late July, as businesses were reopening and life was resuming in some fashion, he was still making ear savers when asked, even as he headed back to work and readied himself for the start of the fall semester on the Notre Dame campus.

“I can’t wait. I’m not at all nervous,” he said. “I’m really looking forward to seeing everyone.”

“I can’t wait. I’m not at all nervous,” he said. “I’m really looking forward to seeing everyone.”

Zufelt, who earned his B.A. in business and economics from Ursinus College and his master’s degree in analytics from Villanova, has a long family legacy with Notre Dame. “We’re fourth-generation Domers on my dad’s side and third generation on my mom’s. I grew up under the religion of ‘Touchdown Jesus.’ When I stepped on campus for the first time in fifteen years for the ND/Pitt game in 2018, I texted my mom, ‘I feel like I’m home.’”